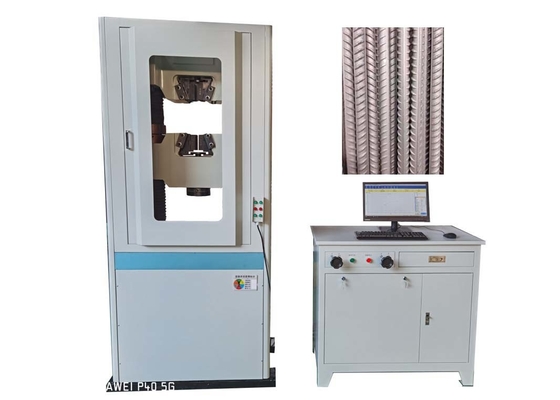

BS4449 水力用ユニバーサル試験機械 コンクリートの強化用鋼

作業原理:

主機には6列のフレーム構造があり,4列と2つのリードスクリューがあります.上横梁と下横梁は伸縮スペースを形成します.下の横梁と作業台が圧縮空間を構成する電気コントローラ,サーボバルブ,負荷センサー,移動センサー,拡張計,コンピュータから構成され,閉ループのサーボ制御システムを形成します.このシステムは,自動的に正確にテストプロセスを制御し,テストフォースなどのテストパラメータを自動的に測定することができます変形や変形

価格優位性

社内の研究開発を 強化し 加工センターを設立することで 核心部品を 独立して製造しています品質を一貫して保ちながら サプライチェーン全体でコストを削減できます低価格で劣等な代替品とは対照的に 高品質の製品は 長期的により大きな節約をもたらします顧客のメンテナンスコストを削減し 運用効率を向上します競争力のある価格と優れた品質の組み合わせは 顧客にとって 実質的な利益をもたらします

特徴:

高精度測定

高精度な負荷センサー,移動センサー,エクステンソメーターを搭載し,テスト中に力,移動,変形などのパラメータを正確に測定することができます.フォース値の精度は通常 ±0 に達します.0.5%

様々な制御モード

フォース制御,変形制御,および移動制御を含む複数の制御モードをサポートします. テスト中に,事前に設定されたプログラムに応じて異なるモード間でシームレスに切り替えることができます..

広い速度範囲

速度を極低から比較的高い速度まで段階なく調整できるため,様々な材料や試験タイプに対する負荷速度要件を満たします.05~200mm/min.

自動制御とデータ処理

テストプロセスはコンピュータソフトウェアによって自動的に管理され,テストデータを自動的に収集,記録,処理することができます.試験結果,例えば指定された不比例の長さ等を計算するストレッチ強度,弾性モジュール,長さ,リアルタイムでテスト曲線を表示し,印刷されたテストレポートを生成することができます.

多機能テスト

プレストレスコンクリート鋼の張力試験に加えて,他の金属,非金属,固定装置と補助道具を交換することによって.

基準:

ISO 6892,ISO 6934 BS4449,ASTM C39,ISO75001,ASTM A370,ASTM E4,ASTM E8およびBSEN規格について

主な技術パラメータ:

| モデル |

WAW-600G |

| 構造 |

4つの柱と2つのスクリュー |

|

コントロール方式

|

荷付けプロセスの手動制御,コンピュータ自動データ処理 |

| 最大負荷 (kN) |

600kN |

| 負荷精度 |

≤±0.5% |

| 負荷範囲 |

2%~100%FS |

| イソキネティックストレスの制御範囲 |

2-60 (N/mm2•S-1) |

| ストレス率の誤り |

≤±0.5% |

| 負荷解像度 |

1/600000 |

| 変形測定範囲 |

2%~100%FS |

| 変形精度 |

≤±0.5% |

| 移動解像度 (mm) |

0.01 |

| 移動エラー |

≤±0.5% |

| マックス・ピストン・ストローク (mm) |

250 |

| ピストンの最大移動速度 |

0.5-100 mm/min 手動調整 |

| クロスヘッドの上げ速度 |

300mm/min |

| 最大 張力試験空間 |

700mm (カスタマイズできる) |

| 最大圧縮試験空間 |

600mm (カスタマイズできる) |

| 固定方法 |

液圧クランプ |

| 丸い試料の固定範囲 (mm) |

φ13-φ40 mm ((13-26,26-40) |

| 平面の試料の固定範囲 (mm) |

0-15,15-30mm |

| 平面標本の固定幅 (mm) |

80 |

| 圧縮プレートの大きさ (mm) |

200*200 |

| 曲がりロール距離 (mm) |

450 |

| 曲がりロールの幅 (mm) |

120 |

| 電源 |

3相,AC380V,50Hz (カスタマイズ可能) |

| 体重とサイズ |

2100KG,960mm*750*2270mm |

梱包と輸送:

よく 聞かれる 質問

Q1. あなたの会社は 貿易会社ですか? それとも 工場ですか?

A: 工場+貿易 (統合) 18年間,試験装置の分野に専念し,14年間の輸出経験.

Q2. 最も適した製品をどのように選ぶか?

A: 私たちのプロのライムは,あなたが行う必要があるテストの種類と必要な仕様を教えてくれる限り,最高の提案を与える

Q3 デルベリー項は何ですか?

A: ほとんどの場合,私たちは工場でストックを持っています. ストックがない場合,通常,配送時間は,預金受領後15-20日です.

緊急事態に 直面している場合は 特別な準備をします

Q4.カスタマイズサービスを受け入れるのですか?

A: はい,もちろん,私たちは標準マシンだけでなく,あなたの要求に応じてカスタマイズされたマシンも提供することができます.

あなたのニーズを満たすために最善を尽くします.

Q5. 注文前に工場を訪問できますか?

A: はい,私たちは温かく歓迎し,誠にあなたまたはあなたのチームを私たちの工場を訪問するように招待します.私たちはホテルを整理し,空港からあなたをピックアップするのに役立ちます.

Q6 保証はどうですか?

A: 一般的に,私たちの保証は1年 witrinの保証期間です. 私たちは技術サポートとパーツ交換を提供することができます. 必要に応じて,私たちのエンジニアはより良いサービスのためにあなたの場所に行くことができます.

Q7. 機械の梱包はどうですか? 輸送中に安全に保護されていますか?

A: 私たちの機械は標準の輸出木箱で詰め込まれています. 損傷しません. 我々は多くのテストマシンを海外に海または空間で損傷なく配達しました.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!