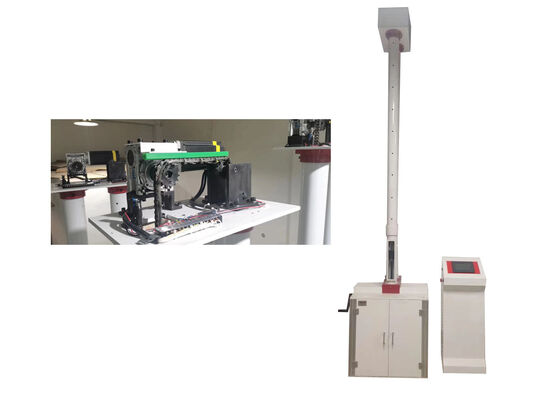

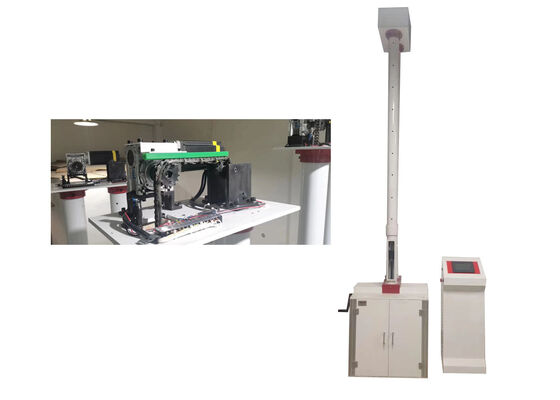

Drop Hammer Test Equipment for Accurate Impact Strength Measurement

This testing machine is extensively utilized for external load impact strength testing of plastic pipes, plastic sheets, and non-metallic materials. Test specimens are impacted by a drop hammer—of specified mass and shape—released from a predefined height onto designated positions along the specimen's circumference. This process enables the accurate estimation of the True Impact Rate (TIR) for the product batch or extruder production run.

Maximum Acceptable TIR: 10% (aligned with industry quality control standards)

As a professional quality inspection instrument, it is widely applied in the construction industry, manufacturing enterprises, chemical sector, universities, and other R&D or quality control institutions.

Compliance Standards

GB/T14152, GB/T10002.1, GB/T5836.1, GB/T13664, GB/T16800, ASTM D2444, ISO4422, ISO3127, BSEN1411 and BSEN744.

Equipment Characteristics

Three-Tier Safety Protection System

- Tier 1: Sample Chamber Door Safety Guard

- Tier 2: Observation Window Safety Protection (temporarily not fitted)

- Tier 3: Upper & Lower Travel Limit Safety Mechanism

This multi-layered safeguard guarantees operator and specimen safety throughout the entire testing cycle.

High-Speed Lifting Capability

Fitted with a high-torque stepping motor, the device achieves a peak lifting velocity of 250 mm/s. It can raise the hammer from ground zero to 2 meters in merely 8 seconds, drastically cutting down test cycle time and boosting overall efficiency.

Precision Hovering System

Employing a multi-step speed regulation program, the machine ensures smooth and accurate hammer positioning with zero offset. This stability underpins consistent test conditions, delivering dependable and reproducible data results.

Enhanced Drop Hammer Tube with Exhaust Structure

The drop hammer tube is designed via 3D modeling, integrated with vent holes to reduce wind resistance to a minimum during hammer descent. It also incorporates a reinforced clamping mechanism to avert tube deformation or functional breakdown, ensuring long-term operational sturdiness.

Pneumatic Hammer Clamping & Release Mechanism

Replacing conventional electromagnetic hammer setups, the system adopts a high-pressure pneumatic configuration—equipped with a 300N long-stroke dual cylinder. The hammer face is furnished with a rubber tendon pad, ensuring steady impact force and preventing specimen damage. Both clamping and release functions leverage pneumatic technology, fundamentally resolving problems such as cable wear, wire breakage, and electrical leakage. The built-in pneumatic automatic locking device ensures safe and dependable operation.

Integrated Modular Architecture

- Mechanical Assembly: Utilizes standard aluminum alloy profile construction, enabling standardized processes, modular installation, lightweight design, and high structural rigidity.

- Electrical Control Unit: Configured with a 7-inch touchscreen and Delta PLC, facilitating user-friendly operation, stable control performance, and straightforward maintenance.

High-Grade Component Selection

All core components are globally procured for superior reliability and performance:

- Cylinder: Adker brand

- Touchscreen: Delta brand

- PLC: Delta brand

- Power Supply: Mean Well (Taiwan, China) brand

The machine is outfitted with comprehensive safety safeguards, including electrical leakage protection, short-circuit prevention, anti-static measures, anti-interference technology, power failure protection, and misoperation prevention—covering electrical, mechanical, and software aspects.

Advanced Automation Capability

The instrument boasts end-to-end automation, encompassing automatic zero-point calibration, automatic hammer elevation, automatic hammer release, and automatic test execution. This reduces manual involvement, enhances testing efficiency, and mitigates human error.

Technical Parameters

| Parameter |

Specification |

| Model |

XJL-450M |

| Ambient temperature |

10℃-35℃ |

| Drop hammer quality |

0.5kg-5kg |

| Hammer diameter |

D25mm, D90mm (customizable) |

| Height of the fall |

50mm-2000mm, error≤±2mm |

| Diameter of the sample |

Φ10mm-Φ450mm (customizable) |

| Deviation of impact center from fixture center |

≤2mm |

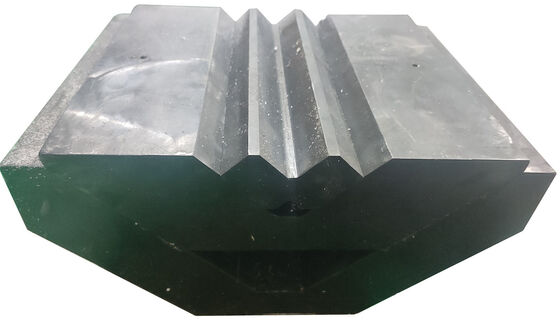

| V-type supporting |

120° |

| Power source |

220VAC±10% |

| Outline dimension |

730mm×700mm×3650mm |

| Net weight |

300kg |

Standard Configuration

| Component |

Quantity |

| Host |

One set |

| Electric cabinet |

One set |

| The hammer body |

One set |

| Power line |

One piece |

| V-type supporting |

Two pieces |

| Operating tool (wrench) |

One set |

Frequently Asked Questions

Q1: What is the maximum impact energy range of the drop hammer impact testing machine?

A1: The standard model offers an impact energy range of 0.5-50 J, with optional extensions to 100 J for high-strength material testing. It supports adjustable energy levels to meet diverse test requirements for plastic pipes, sheets, and non-metallic materials.

Q2: What are the available drop heights and hammer mass specifications?

A2: The adjustable drop height ranges from 50-2000 mm (precise to ±1 mm). Hammer masses are configurable in increments of 0.1 kg, with standard options from 0.2 kg to 10 kg—covering common test standards such as ISO 3127 and ASTM D 2444.

Q3: How accurate is the machine's drop height and impact force control?

A3: The drop height accuracy is ±0.1% of the set value (or ±1 mm, whichever is smaller). The pneumatic release mechanism ensures zero initial velocity deviation, while the force sensing system (optional) provides impact force accuracy of ±1% FS—guaranteeing test data reliability.

Q4: What safety protection mechanisms does the machine have to prevent operational risks?

A4: It features a three-tier safety system: ① Sample chamber interlock (machine stops if the door is open); ② Upper/lower travel limit switches; ③ Emergency stop button. The drop hammer tube is also reinforced to avoid structural damage during high-energy impacts.

Q5: Is the machine compatible with international testing standards, and what materials can it test?

A5: It fully complies with ISO 3127, ASTM D 2444, GB/T 14152, and BS EN 14411 standards. Applicable materials include plastic pipes (PVC, PE, PP), plastic sheets, rigid non-metallic composites, and other materials requiring external impact strength evaluation.

Q6: What is the automation level of the machine, and can it record test data automatically?

A6: It supports full-process automation: automatic zero-point calibration, hammer lifting, positioning, release, and test result calculation. Equipped with a 7-inch touchscreen and PLC, it can store up to 10,000 test records (including impact energy, drop height, TIR value) and export data in Excel/CSV format.

Q7: How long is the service life of key components, and what maintenance is required?

A7: Core components (pneumatic cylinder, stepper motor, PLC) have a service life of ≥50,000 test cycles. Routine maintenance includes monthly lubrication of the guide rail, quarterly inspection of the sealing ring, and annual calibration of the drop height and hammer mass.

Q8: What environmental conditions are required for the machine to operate normally?

A8: Operating temperature: 10-35 °C; relative humidity: ≤85% (non-condensing); power supply: AC 220V±10% 50Hz (or 110V±10% 60Hz, customizable); no strong electromagnetic interference or vibration in the working area.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!