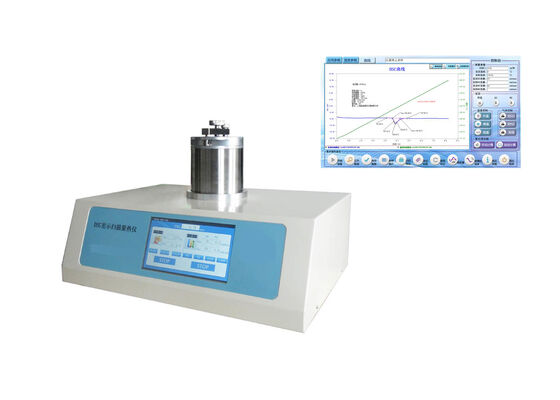

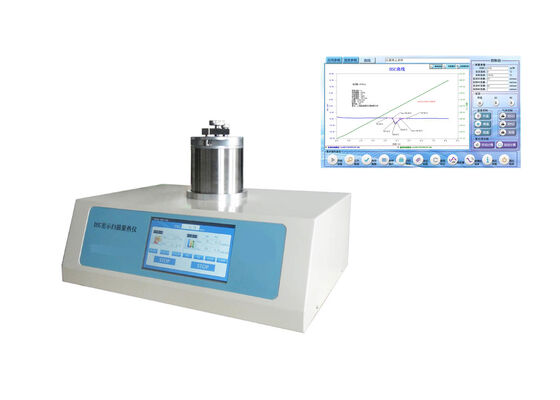

Durable Differential Scanning Calorimetry Machine for Precise Thermal Measurement of Plastics Polymers and Material Testing

Frequently Asked Questions

Q1: What is the core working principle of a DSC machine?

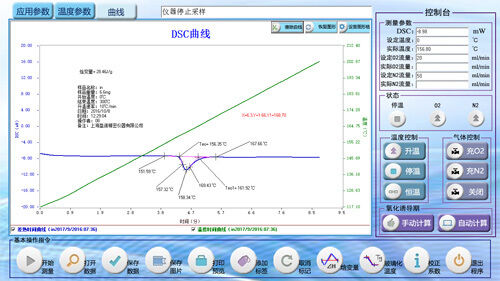

The DSC machine operates by measuring the heat flow difference between a sample and an inert reference material as both are subjected to a programmed temperature cycle (heating, cooling, or isothermal). This enables quantitative analysis of heat-associated physicochemical changes in the sample, such as phase transitions, melting, crystallization, and thermal decomposition.

Q2: What key physicochemical properties can a DSC machine test?

It can precisely quantify critical parameters including glass transition temperature (Tg), melting point (Tm), melting enthalpy, crystallization behavior, crystallization enthalpy, phase transition enthalpy, thermal stability, curing/crosslinking degree, and oxidation induction period (OIP).

Q3: What are the typical temperature range and temperature accuracy of a standard DSC machine?

Standard models offer a temperature range of -150 °C to 700 °C (extendable to 1500 °C for high-temperature variants). Temperature accuracy is ±0.1 °C, with temperature resolution up to 0.01 °C—ensuring precise control of the programmed temperature cycle.

Q4: Which materials are compatible with DSC testing?

It is widely applicable to polymers (plastics, rubbers, fibers), inorganic materials, pharmaceuticals, food ingredients, oils and fats, composites, and other materials requiring thermal property analysis—covering R&D, quality control, and failure analysis scenarios.

Q5: Does the DSC machine comply with international testing standards?

Yes, it fully complies with major international standards such as ISO 11357 (polymers), ASTM E967/E968 (general DSC methods), GB/T 19466 (plastics), and USP <891> (pharmaceuticals)—ensuring test results are recognized globally.

Q6: What is the sample requirement for DSC testing, and how is data processed?

The recommended sample weight ranges from 2-10 mg (depending on material type). The machine is equipped with a high-sensitivity heat flow sensor (sensitivity ≤0.1 μW) and professional analysis software, which automatically records test curves (heat flow vs. temperature/time) and calculates key parameters. Data can be exported in Excel/CSV/PDF formats for further analysis.

Q7: What maintenance is required for the DSC machine, and what is the service life of core components?

Routine maintenance includes annual calibration of temperature and heat flow (using standard reference materials like indium), and regular cleaning of the sample pan. Core components (sensor, heating/cooling module) have a service life of ≥50,000 test cycles. We provide calibration protocols and technical support for maintenance.

Q8: Can the DSC machine be customized for specific testing needs?

Yes, customization options are available, including extended temperature ranges (low-temperature cryogenic modules or high-temperature furnaces), specialized sample pans (hermetic, pressure-resistant), and tailored software functions (e.g., kinetic analysis modules for curing reactions)—adapting to unique application scenarios.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!